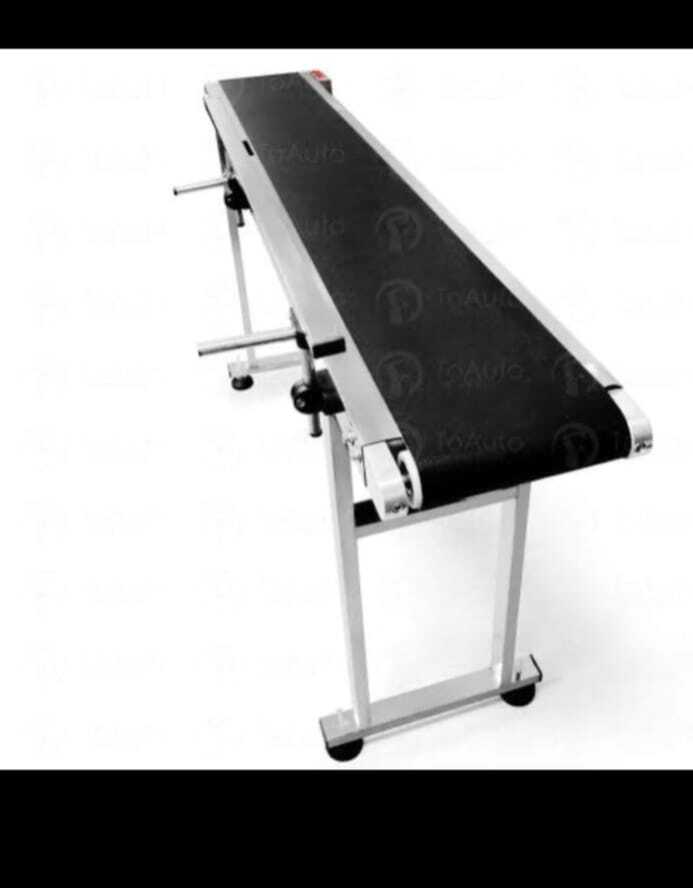

8 INCH CONVEYOR

Product Details:

8 INCH CONVEYOR Price And Quantity

- 1 Number

- 18000 INR/Number

- 15000.00 - 18000.00 INR/Number

8 INCH CONVEYOR Trade Information

- All India

Product Description

An 8-inch conveyor is a type of material handling system designed to transport products or materials from one location to another efficiently. Here™s a technical description of its components and functionalities:

Components

1. Belt Width The conveyor features an 8-inch-wide belt that can accommodate various items, from small parts to larger packages.

2. Frame Structure Typically constructed from durable materials like steel or aluminum, the frame provides stability and support for the conveyor system.

3. Drive System Includes a motor and gearbox that power the conveyor. The motor's specifications (e.g., horsepower and RPM) depend on the application requirements.

4. Rollers Positioned beneath the belt, these help reduce friction and facilitate smooth movement. They can be fixed or adjustable, depending on the design.

5. Belt Material The conveyor belt can be made from various materials (e.g., PVC, rubber, metal) depending on the application's needs (e.g., heat resistance, chemical resistance).

6. Idlers Support the belt and help maintain its tension and alignment. They are critical for ensuring smooth operation.

7. Controls Include a control panel with options for starting/stopping the conveyor, adjusting speed, and emergency stop functions.

8. Side Guides Optional components that can be added to keep products centered on the belt and prevent them from falling off.

Functionality

- Material Transport Designed to move materials horizontally or at an incline, suitable for various applications such as packaging, assembly, and sorting.

- Speed Control Many models offer adjustable speed settings to match the specific requirements of the production process.

- Modular Design Some conveyors are modular, allowing for easy expansion or reconfiguration as needed.

- Integration Can be easily integrated with other equipment, such as feeders, hoppers, or packaging machines, to create a fully automated system.

Applications

- Manufacturing Used in assembly lines for moving parts between workstations.

- Warehousing Facilitates the movement of products to packing or shipping areas.

- Food Processing Suitable for transporting food products, often designed to meet hygiene standards.

- Distribution Centers Efficiently moves goods through sorting and packaging processes.

Advantages

- Efficiency Increases productivity by automating the movement of materials.

- Flexibility Can be customized in length, height, and configuration to suit specific operational needs.

- Durability Built to withstand industrial environments, ensuring long service life.

This 8-inch conveyor system is essential for optimizing material handling processes across various industries, providing a reliable solution for transporting goods effectively.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free